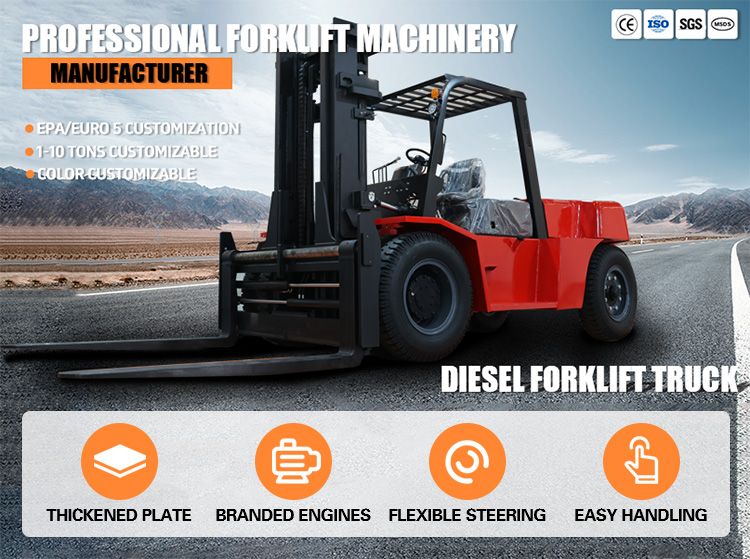

10T Diesel Forklift: Redefining Heavy-Duty Handling with Technological Innovation

In the heavy industrial handling sector, equipment efficiency, durability, and operational comfort are non-negotiable. Our newly launched 10T diesel forklift takes user needs as its core, deeply integrating ergonomic design and cutting-edge technology. It not only tackles heavy-load challenges with ease but also enhances driver comfort through meticulous optimizations, becoming a powerful partner for enterprises to boost productivity and reduce operational costs.

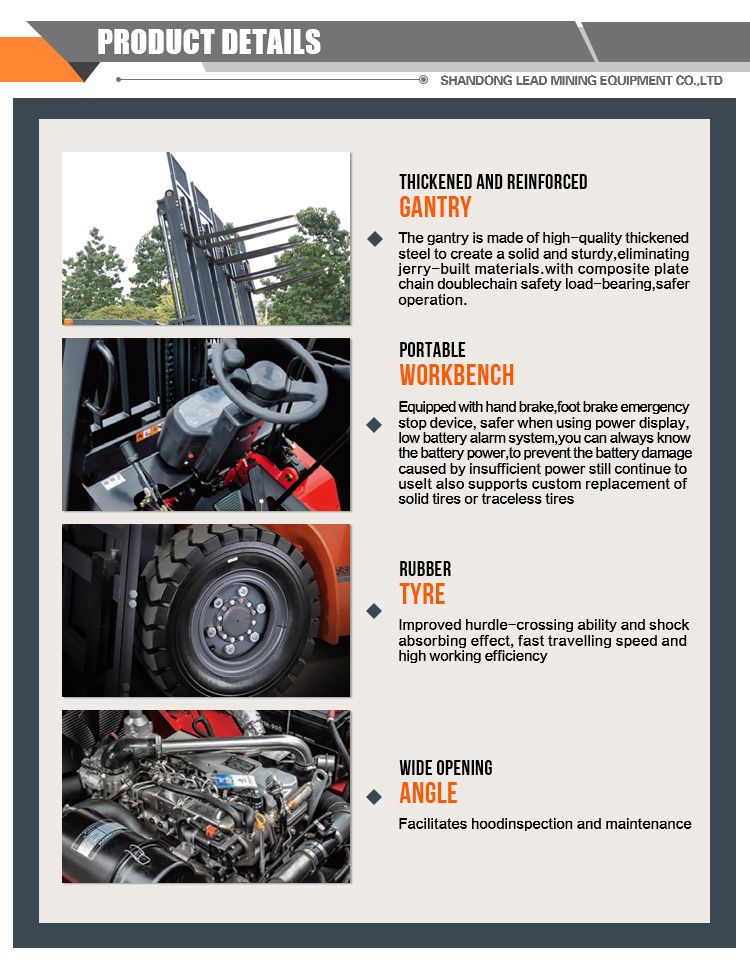

Ergonomic Design: Crafting a Comfortable Working Environment

The 10T diesel forklift embodies ergonomic principles in every detail. The cockpit features a 环抱式 (surrounding) layout, with operation handles, pedals, and the instrument panel precisely positioned according to the natural human operating posture. Drivers can easily reach all controls without frequent body adjustments. The seat offers multi-directional adjustments, including front/back, height, tilt angle, and memory foam shock absorption with lumbar support, effectively reducing fatigue even during long hours of operation. Additionally, the cockpit’s noise isolation and ventilation system, combined with low-vibration design, create a quiet and comfortable operating space.

System Optimization: Ensuring Sustained Engine Efficiency

Comprehensive optimizations of the intake, exhaust, and cooling systems significantly enhance engine performance and lifespan. The intake system features a high-efficiency multi-layer air filter and a high-position air inlet to block dust and gravel, ensuring clean air intake. The exhaust system uses noise-reduction and airflow optimization technology to reduce backpressure and noise pollution. The cooling system is equipped with an intelligent temperature-controlled fan and a large radiator, automatically adjusting cooling intensity based on engine load to prevent performance degradation due to overheating. Tests show these optimizations extend engine maintenance cycles by 40% and reduce failure rates by 35%, saving significant maintenance costs for enterprises.

Dual Power & Transmission Assurance: Stable Performance Guaranteed

Powered by a high-performance diesel engine and advanced transmission system, the forklift delivers strong and stable power. The engine uses high-pressure common rail fuel injection technology to ensure efficient combustion, reducing fuel consumption and emissions while maintaining robust power. The transmission system employs high-precision gear sets and imported hydraulic pumps/valves for smooth power transmission and minimal energy loss. Additionally, intelligent auxiliary devices like a fault diagnosis system and hydraulic oil pressure monitoring continuously monitor system status, alerting operators and locating faults instantly to prevent unexpected breakdowns and ensure continuous operation.

Innovative Adjustment Mechanism: Precise and Convenient Control

The new steering wheel adjustment mechanism allows drivers to quickly find their optimal driving position. Supporting 4-way adjustments (up/down, front/back) with a 30% wider range than traditional forklifts, it features a one-click locking design for smooth adjustments and stable positioning. Whether for tall drivers or complex operations requiring frequent viewpoint changes, this mechanism enables precise control, enhancing both comfort and safety.

Intelligent Interaction System: Real-Time Vehicle Status at Your Fingertips

Equipped with a high-definition LCD digital instrument panel and intuitive HMI (Human-Machine Interface), all critical data is clearly displayed. The dashboard real-time shows over 20 parameters, including speed, load weight, engine RPM, fuel level, and hydraulic pressure, using a large color screen and simple icons for easy reading even in bright light. The touch-responsive interface allows quick function switching and parameter settings via simple gestures. The system also supports data storage and export, facilitating intelligent maintenance management through operational data analysis.

Efficient Braking System: Ensuring Safe and Reliable Operations

Combining drum brakes with a full-hydraulic power braking system, it delivers strong and stable stopping power. The full-hydraulic system reduces operating force significantly, enabling quick and smooth braking with light pedal pressure—more effortless and precise than traditional mechanical brakes. The drum brakes feature special wear-resistant treatments and excellent heat dissipation, maintaining consistent braking performance during continuous use or heavy-load downhill operations to ensure safety.

Wide-View Design: Eliminating Operational Blind Spots

The innovative wide-view molded groove doorframe design minimizes obstructions by optimizing structure and dimensions. Paired with a panoramic windshield and blind-spot assist mirrors, drivers enjoy a near 360° view, clearly observing cargo, equipment, and pedestrians during high stacking, narrow aisle navigation, or complex operations. This proactive risk prediction reduces collision risks and improves efficiency and safety.

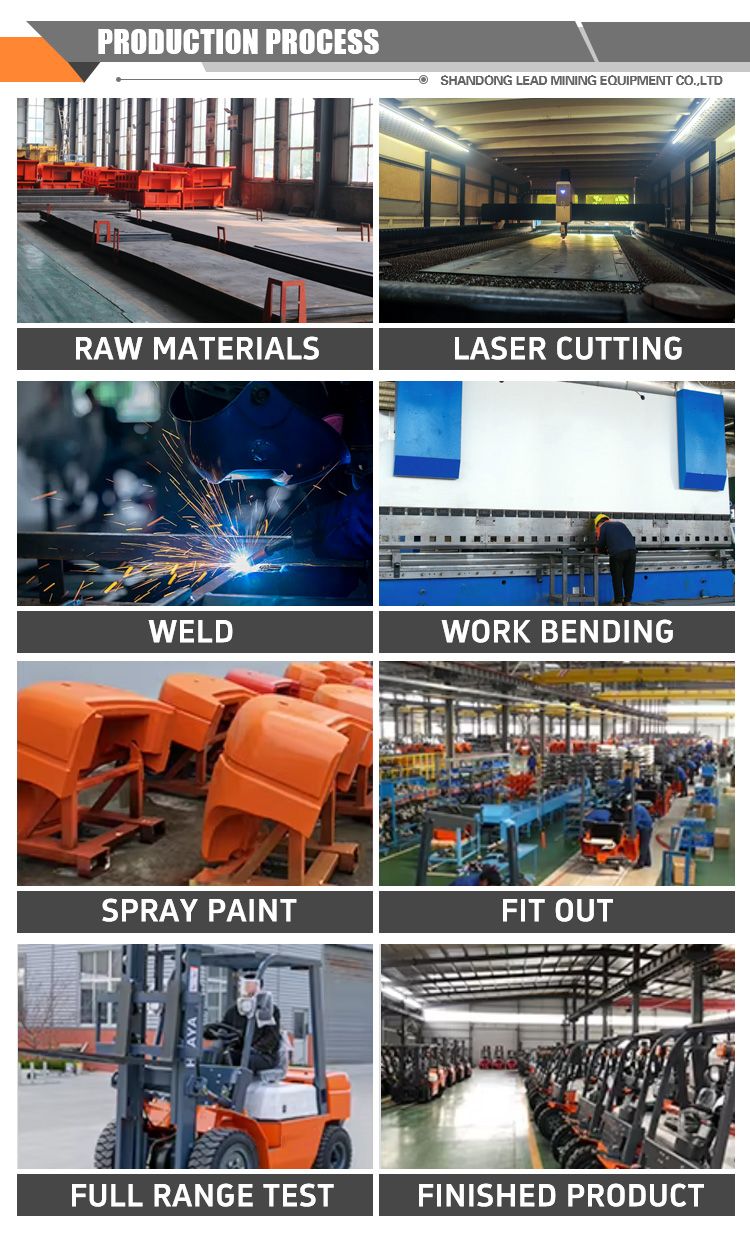

Ingenious Manufacturing: Crafting High-Quality Reliability

Production adheres to strict standards and quality control, with the frame formed from high-strength alloy steel via one-piece molding and heat treatment, enhancing anti-deformation capability by 50%. Key components like hydraulic cylinders and steering knuckles are sourced from international brands to ensure durability and impact resistance. Each forklift undergoes 128 rigorous tests—covering performance, reliability, and safety—to guarantee superior quality and long-term stable operation.

This 10T diesel forklift elevates heavy-duty handling to new heights of efficiency, safety, and comfort through comprehensive technological innovation and user-centric design, making it the ideal choice for enterprises striving for excellence in industrial logistics.