2.6T Four-Cylinder Diesel Forklift: Heavy-Duty Powerhouse for Industrial Handling Excellence

In the realm of heavy-duty material handling, the 2.6T Four-Cylinder Diesel Forklift emerges as an industrial powerhouse, combining robust power configuration with all-scenario adaptability. Equipped with a four-cylinder high-performance engine and a reinforced mechanical structure, it not only breaks through the performance limits of traditional medium-tonnage forklifts but also redefines the standards of efficient handling through human-centric design and safety features.

I. Four-Cylinder Power Core: Sustained Performance & Economic Durability

Featuring a Huichai/Weifang 490/Yunnei four-cylinder diesel engine (42/45kW power), this forklift utilizes high-pressure common rail technology and turbocharging to increase low-speed torque by 30%, effortlessly managing the 2600kg rated lifting capacity. The 3300kg gross vehicle weight, combined with the 1360mm wheelbase and 1380mm track width, ensures high-speed stability and rollover resistance, delivering reliable power output in complex terrains. The high-position air filtration system effectively filters over 95% of dust, and with a 500-hour maintenance cycle, annual maintenance costs are reduced by 20%, balancing power and economy.

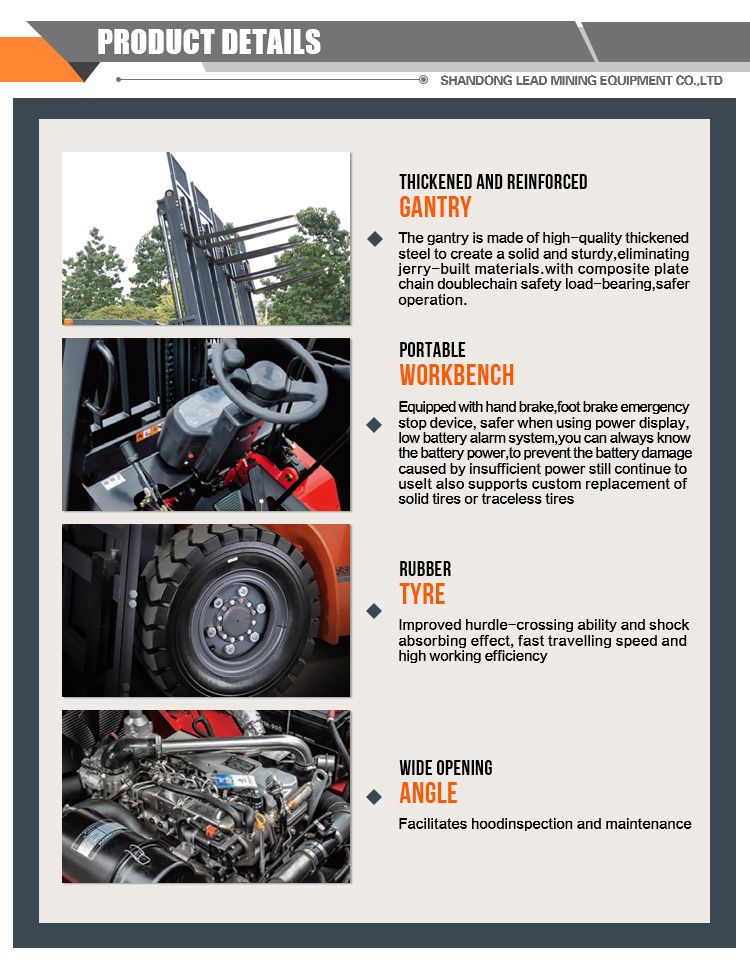

II. Heavy-Duty Structural Design: Industrial-Grade Sturdiness

Reinforced Mast System:With a standard lifting height of 3m, the mast is integrally formed from manganese steel. The 6° forward tilt/12° backward tilt design enhances cargo stability by 25% under full load, suitable for high rack stacking and slope loading/unloading.

Wear-Resistant Fork Assembly:The 1070mm-long forks are forged from alloy steel, with a maximum outer adjustment of 1100mm to accommodate various pallet sizes. The 500mm load center distance meets international standards, ensuring center-of-gravity stability under heavy loads.

Full-Steel Chassis Protection:A 220mm ground clearance and reinforced chassis guard enable smooth passage over gravel and potholed surfaces, while the 15° full-load gradeability conquers complex factory terrains.

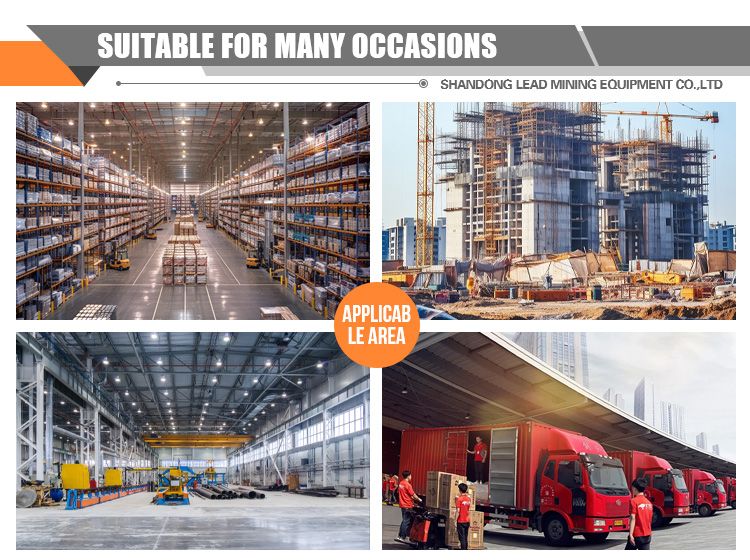

III. Safety & Control: Dual Guarantees for Operational Efficiency

Active Safety Protection:The full-steel overhead guard frame passes ISO 6055 impact tests, withstanding 300kg falling objects;The hydraulic system integrates an anti-burst valve, automatically locking the mast in case of pipe rupture to prevent cargo drops;A seat gravity sensor interlocks with emergency braking, prohibiting vehicle start-up when the driver is unseated to eliminate misoperation risks.

Precision Control Experience:The four-way adjustable steering wheel and suspended shock-absorbing seat adapt to drivers of different heights, reducing fatigue by 30% during long shifts;The full-hydraulic power steering system offers sensitive response, with a 2400mm minimum turning radius for agile maneuvering in narrow aisles. Combined with a wide-view doorframe, front blind spots are reduced by 40%, achieving stacking positioning errors of <3cm.

IV. Intelligent Interaction & Maintenance: Simplified Operations, Reduced Costs

Digital Dashboard:Real-time monitoring of core data (engine speed, oil temperature, load weight, etc.), with automatic audible-visual alarms for overloads/faults. One-click maintenance cycle queries reduce manual monitoring errors.

Low-Maintenance Design:Side-opening engine compartment doors enable quick replacement of consumables (filters, belts, etc.), cutting maintenance time by 50%. Standard 650-9 rear tires and 28×9-15 front tires offer 15% improved wear resistance, with optional off-road tires for extreme conditions.

Energy-Saving Features:Idle start-stop technology and hydraulic energy recovery reduce no-load fuel consumption by 18%, enhancing endurance by 12% at the 20km/h economic speed.

V. Scenario Adaptability: Full-Spectrum Heavy-Duty Solutions

Warehousing & Logistics: The compact body (2900×1380×2200mm) navigates 3m-wide aisles, with a 3m lifting height for standard racks, improving daily handling efficiency by 15% compared to similar models;

Factory Manufacturing: The 2600kg heavy-load capacity handles large component transportation, with a 12° mast back-tilt to prevent cargo slippage, suitable for frequent workshop loading/unloading;

Outdoor Projects: The reinforced chassis and 15° gradeability tackle complex environments (construction sites, ports, etc.), with 99% all-weather operational reliability.

Why Choose the 2.6T Four-Cylinder Diesel Forklift?

Power Leadership: Four-cylinder engine exceeds medium-tonnage limits, excelling in heavy-load starts and sustained operations;

Safety & Reliability: Structural protection and intelligent monitoring ensure end-to-end safety;

Cost Optimization: Long maintenance cycles and low fuel consumption save 25% on full-life cycle costs.

Upgrade Your Handling Efficiency Today—harness the surging power of four cylinders and precision craftsmanship to secure stable, high-efficiency productivity for your heavy-duty operations.